|

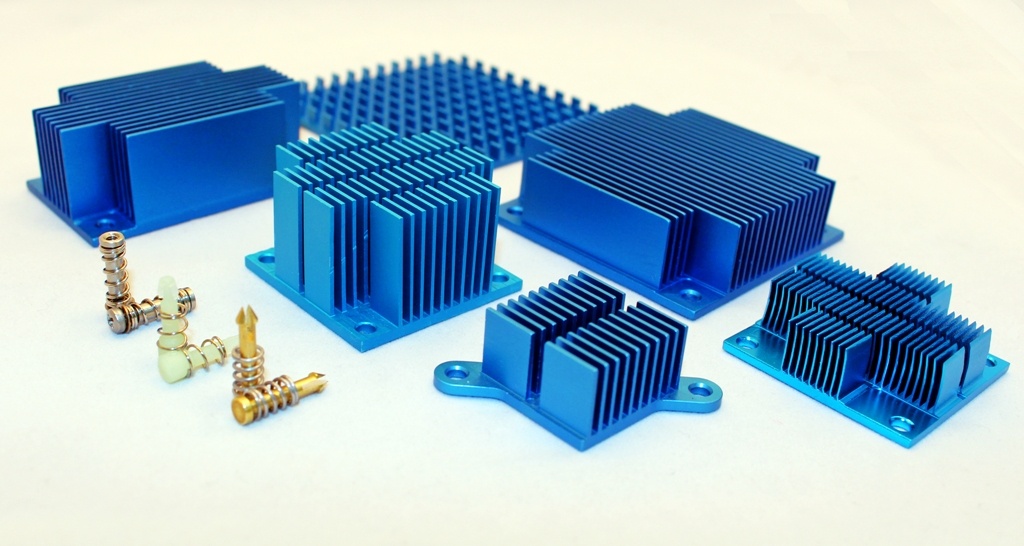

brass, plastic, pem's and 2 different coil spring types are hallmarks of the ats push pin line of heat sinks and a product highlight for the thermal management firm this month. the wide array of material types and attachment options allows an extremely wide variety of applications and environments in with the heat sinks can be deployed. the following is a discussion on the different types and application points for each. the following attachment types will be discussed:

- brass push pin

- plastic push pin

- pem

- music wire coil spring

- stainless steel coil spring

brass push pin attachment

brass push pins are useful for applications that are corrosive, high heat, and require a strong, durable, material for attachment. brass can also be used in situations where it is important that sparks not be struck, as in fittings and tools around explosive gases (1). care must be taken not to use this attachment in environments that include ammonia or that release ammonia as ammonia can cause stress corrosion cracking in brass. brass can often be cheaper than the same attachment in stainless steel since brass costs much less to machine. brass is a reasonably good conductor of heat as well, increasing the overall thermal managment of an application where it used to secure a heat sink (2).

plastic push pin attachment

plastic push pins are useful for applications where the push pin heat sink attachment should not conduct heat or electricity. their lightweight make them a good choice where weight is a critical factor in a design. plastic is also a good option where there might be water or high humidity. corrossion and chemical resistance are another two advantage of plastics. as with any plastic fastner, the plastic itself has to be particularly robust in order to handle the strain of fastener insertion and subsequent high stress around the fastener (3)(4).

pem attachment

pem attachments are perfect for applications where there is only a plain, round hole. they provide high pushout and torque our resistance. the holes for these fastners do not need to be specially prepared by deburring or chamfering. pems are also good for meeting dfma requirements since there are fewer parts to handle and fewer assembly steps in using them (5).

stainless steel coil spring

stainless steel is an alloy somewhat similar to ordinary steels except that it contains from 12 to 20 percent chromium which makes it completely resistant to atmospheric corrosion. stainless steel and music wire are the two most commonly used materials in spring manufacture (6).

music coil spring

music wire is the best-quality, most generally used cold-drawn high-carbon spring steel. it has a high tensile strength, high elastic limit, and can withstand high stresses under repeated loadings. this type of wire is also called "piano wire", because of it's use in stringed instruments, especially the piano (6).

finally, the best attachment choice for the ats push pin heat sinks is based on the unique application that an engineer has for their thermal managment design. whatever that application may be, ats's attachment kits are designed to provide a wide range of solutions, reducing an engineers design time while having an excellent solution. ats announced their push pin heat sinks in january of this year. a data sheet with various push pin push pin options that ats has can be found at digi-key here.

ats push pin heat sink line - straight fin

references

1. canadian centre for occupational health and safety, "non-sparking tools", http://www.ccohs.ca/oshanswers/safety_haz/hand_tools/nonsparking.html

2. machine design, "comparing brass and stainless steel inserts", http://machinedesign.com/materials/comparing-brass-versus-stainless-steel-threaded-inserts

3. product design & development, "the art of using plastic instead of metal", http://www.pddnet.com/articles/2005/04/art-using-plastic-instead-metal

4. mechanical design, "joining plastic", http://machinedesign.com/fasteners/joining-plastic

5. pem, the self clinching fastner handbook, http://www.pemnet.com/fastening_products/pdf/handbook.pdf

6. angelica spring, "stainless steel music wire", http://angelicaspringcompany.com/index.php?stainless%20steel%20music%20wire

|