|

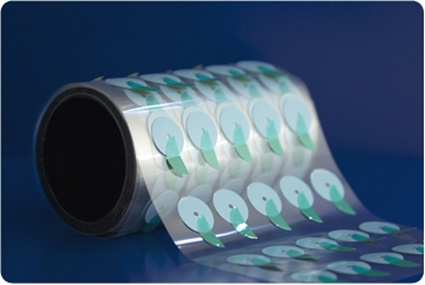

micro-faze is a new, revolutionary thermal interface film formulated with non-silicone thermal grease. it was developed by aos to offer the lowest thermal resistance in a thermal interface without the mess of grease. micro-faze does not require burn-in to form into place. micro-faze is not phase change material. it's benefits include:

- low thermal resistance with minimum force

- naturally tacky, non-silicone

- conforms with coefficient of thermal expansion

- (cte) deficiencies

- uniform film and exact thickness of thermal gease

- with each application

- no phase change required for heat transfer to take place—good low temp performance

- durable resistance over usable lifetime

- easily stored at a wide range of temperatures

-

features and benefits

- retains all the performance advantages of thermal grease but in the form of a thermal pad

- requires minimum force to achieve total interface contact

- allows for total “wetting action” to fill all micoscopic surface voids without changing phase

- a positive coefficient of thermal expansion (cte) deficiencies the wetting action for total interface contact

- heat transfer takes place at any temperature (unlike phase change materials), making micro-faze an excellent choice for cold plate applications

- offers maximum heat transfer capability for

- power component

- excellent replacement for phase change materials and silicone pads

- is a “drop-in-place” product that is easy to use and handle

- in a manufacturing environment

- naturally tacky—no adhesive, fiberglass or other

- non-conductive material is used that may penalize

- thermal resistance

- microscopically changes to fill all micoscopic voids

- on part surfaces

- does not pump out!

for more information, contact:

aos thermal compound

http://www.aosco.com

22 meridian road | suite #6

eatontown, nj 07724

toll free (888)-662-7337

|